- YE2 series high efficiency three-phase asynchronous motor

- YE3 series super high efficiency three-phase asynchronous motor

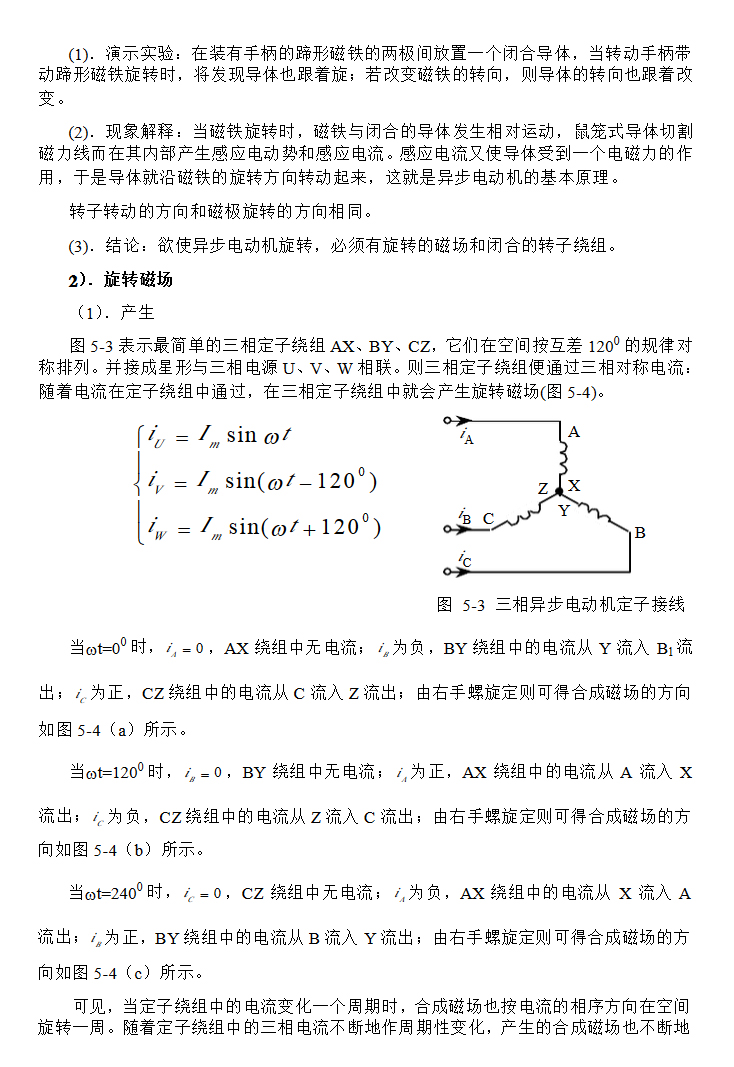

- YVF2 series frequency conversion speed regulation special three-phase asynchronous motor

- YD series pole-changing three phase asynchronous motor

- YDT series dedicated fan pump pole-changing three-phase asynchronous motor

- YSF、 YT series energy saving fan three-phase asynchronous motor

-

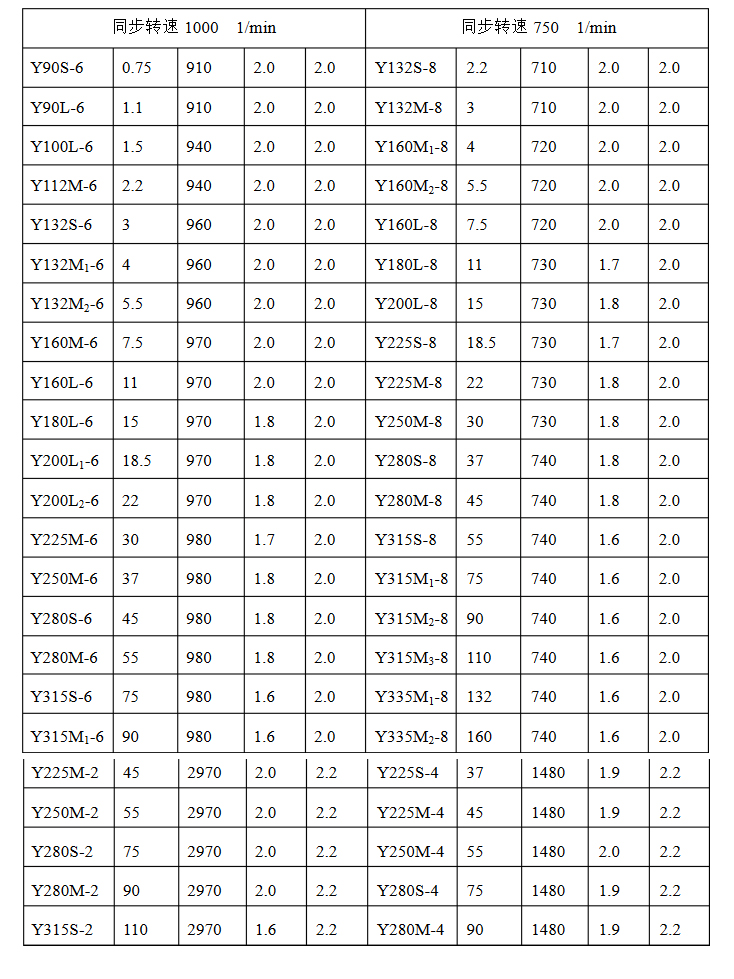

Technical data of Y series three-phase asynchronous motor2016-12-30

Technical data of Y series three-phase asynchronous motor2016-12-30Y series three-phase asynchronous motor technical data 1

Y series three-phase asynchronous motor technical data 2

Notes:Y series motor model consists of four parts: the first part of the Chinese phonetic alphabet Y asynchronous motor; second part digital representation base center(frame without foot, with the same frame with feet); the third part English letter code base length (S - M - in short, a base seat, L long A letter, the figure after) code of core length; the fourth part line after digital motor pole number. For example, the motor model Y132S2-2 is different Step motor, shaft center height 132mm, short base, pole number is 2.

-

The structure and working principle of three phase asynchronous motor2016-12-29

The structure and working principle of three phase asynchronous motor2016-12-29

-

Speed regulation mode2016-12-29

Speed regulation mode2016-12-29Variable pole speed adjusting method

The speed regulation method is to change the stator winding connection mode to change the cage motor stator pole number to achieve the speed regulation

The characteristics are as follows:

1, with a hard mechanical properties, good stability;

2, no slip loss, high efficiency;

3, wiring is simple, easy to control, low prices;

4, speed, bigger, can not get smooth speed;

5, can be used with the voltage regulator, electromagnetic slip clutch with high efficiency, smooth speed regulation characteristics.

The method is applicable to the production of machines without the need of stepless speed regulation, such as metal cutting machine tools, elevators, lifting equipment, fans, pumps, etc..

Variable frequency speed regulation method

Variable frequency speed regulation is the speed control method to change the frequency of the motor stator power supply, so as to change the synchronous speed. The main equipment of frequency conversion system is to provide variable frequency power supply inverter, the inverter can be divided into AC DC AC inverter and AC AC converter into two categories, most of the domestic use of AC-DC-AC frequency converter. Its characteristics:

1, high efficiency, no additional loss in the speed regulation process;

2, a wide range of applications, can be used for cage asynchronous motor;

3, speed range, hard, high precision;

4, complex technology, high cost, maintenance difficulties.

The method is suitable for high accuracy and good speed regulation.

Cascade speed regulation method

Cascade speed regulation refers to the winding motor rotor circuit can be adjusted into the additional potential to change the motor rotation, to achieve the purpose of speed regulation. Most of the differential power is absorbed by the additional potential which is connected in series, and then an additional device is used to return the absorbed differential power to the power grid or to convert the energy to be utilized. According to the difference of power absorption and utilization, cascade speed regulation can be divided into motor cascade speed control, mechanical cascade speed control and thyristor cascade speed regulation, the use of thyristor cascade speed regulation, which is characterized by:

1, can be in the process of speed difference between the loss of feedback to the power grid or production machinery, high efficiency;

2, equipment capacity and speed range is proportional to the investment, suitable for the production of mechanical speed range at rated speed 70%90%;

3, speed control device failure can switch to full speed operation, avoid production;

4, thyristor cascade speed control power factor is low, the influence of harmonic.

The method is suitable for the use of fan, water pump, rolling mill, mine hoist and extruder.

Resistance speed regulation method

Wirewound asynchronous motor rotor string into additional resistance, the motor slip up motor in low speed

Function。 The greater the resistance, the lower the speed of the motor. This method is simple and easy to control, but the differential power is consumed in the form of heat. Is a class speed control, mechanical characteristics of soft.

Stator voltage regulating speed regulating method

When changing the stator voltage of the motor, a group of different mechanical characteristics curves can be obtained. Due to the torque of the motor is proportional to the square of the voltage, the maximum torque is decreased, and the speed range is small. In order to expand the range of speed, pressure and speed adjustment should be rotorresistance value cage motors such as large torque motor, speed regulator for use, or frequency sensitive resistors in series wound motor. In order to expand the scope of stable operation, when the speed of 2:1 or more occasions should be used to control the feedback to achieve the purpose of automatic speed adjustment.

The main device of voltage regulation and speed regulation is a kind of power supply which can supply voltage variation. The commonly used methods of voltage regulation are series saturable reactor, self coupling transformer and thyristor voltage regulator. Thyristor voltage regulation is the best. Characteristics of voltage regulation and speed regulation:

1, the voltage regulating circuit is simple, easy to achieve automatic control;

2, in the process of adjusting the pressure difference in the form of power consumption in the rotor resistance, low efficiency.

3, pressure regulating speed is generally applicable to the following production machinery 100KW.

Motor speed regulating method

The electromagnetic speed regulating motor is composed of three parts: a cage motor, an electromagnetic slip clutch and a direct current excitation power supply (controller)

A. The DC excitation power supply is small, usually composed of single phase half wave or full wave thyristor rectifier.

The electromagnetic clutch is composed of three parts: the armature, the magnetic pole and the exciting winding. There is no mechanical connection between the armature and the latter. The rotor of the motor armature and the coaxial connection called active part, driven by the motor; magnetic pole for coupling with load docking said driven part. When the armature and the magnetic pole are all static, such as the excitation winding is connected with the direct current, a plurality of poles with alternating polarity of N and S are formed along the circumference of the air gap. When the armature rotates with the drive motor, the armature and pole between relative movement and makes electric armature inductionproduced eddy thiseddy and flux produced by the interaction of torque to drive the rotor poles rotating in the same direction, but its speed constant below the armature speed of N1, it is a slip speed control mode of DC excitation the current change slip clutch, clutch can change the output torque and speed. Speed regulation characteristics of electromagnetic speed regulating motor:

Device structure and control circuit is simple, reliable operation, easy maintenance;

1, speed smooth, stepless speed regulation;

2, the impact on the power grid;

3, speed loss, low efficiency.

The method is suitable for medium and small power, and requires the production of flat sliding, short time and low speed operation.

Coupler speed regulating method

Hydraulic coupler is a kind of hydraulic transmission device

-

Fault handling2016-12-29

Fault handling2016-12-29

绕组是电动机的组成部分,老化、受潮、受热、受侵蚀、异物侵入、外力的冲击都会造成对绕组的伤害,电机过载、欠电压、过电压,缺相运行也能引起绕组故障。绕组故障一般分为绕组接地、短路、开路、接线错误。如今分别说明故障现象、产生的原因及检查方法。 绕组接地指绕组与铁心或与机壳绝缘破坏而造成的接地。

1、故障现象

机壳带电、控制线路失控、绕组短路发热,致使电动机无法正常运行。

2、产生原因

绕组受潮使绝缘电阻下降;电动机长期过载运行;有害气体腐蚀;金属异物侵入绕组内部损坏绝缘;重绕定子绕组时绝缘损坏碰铁心;绕组端部碰端盖机座;定、转子磨擦引起绝缘灼伤;引出线绝缘损坏与壳体相碰;过电压(如雷击)使绝缘击穿。

3.检查方法

⑴观察法。通过目测绕组端部及线槽内绝缘物观察有无损伤和焦黑的痕迹,如有就是接地点。

⑵万用表检查法。用万用表低阻档检查,读数很小,则为接地。

⑶兆欧表法。根据不同的等级选用不同的兆欧表测量每组电阻的绝缘电阻,若读数为零,则表示该项绕组接地,但对电机绝缘受潮或因事故而击穿,需依据经验判定,一般说来指针在“0”处摇摆不定时,可认为其具有一定的电阻值。

⑷试灯法。如果试灯亮,说明绕组接地,若发现某处伴有火花或冒烟,则该处为绕组接地故障点。若灯微亮则绝缘有接地击穿。若灯不亮,但测试棒接地时也出现火花,说明绕组尚未击穿,只是严重受潮。也可用硬木在外壳的止口边缘轻敲,敲到某一处等一灭一亮时,说明电流时通时断,则该处就是接地点。

⑸电流穿烧法。用一台调压变压器,接上电源后,接地点很快发热,绝缘物冒烟处即为接地点。应特别注意小型电机不得超过额定电流的两倍,时间不超过半分钟;大电机为额定电流的20%-50%或逐步增大电流,到接地点刚冒烟时立即断电。

⑹分组淘汰法。对于接地点在铁芯心里面且烧灼比较厉害,烧损的铜线与铁芯熔在一起。采用的方法是把接地的一相绕组分成两半,依此类推,最后找出接地点。

此外,还有高压试验法、磁针探索法、工频振动法等,此处不一一介绍。

4.处理方法

⑴绕组受潮引起接地的应先进行烘干,当冷却到60——70℃左右时,浇上绝缘漆后再烘干。

⑵绕组端部绝缘损坏时,在接地处重新进行绝缘处理,涂漆,再烘干。

⑶绕组接地点在槽内时,应重绕绕组或更换部分绕组元件。

最后应用不同的兆欧表进行测量,满足技术要求即可。 绕组短路由于电动机电流过大、电源电压变动过大、单相运行、机械碰伤、制造不良等造成绝缘损坏所至,分绕组匝间短路、绕组间短路、绕组极间短路和绕组相间短路。

1.故障现象

离子的磁场分布不均,三相电流不平衡而使电动机运行时振动和噪声加剧,严重时电动机不能启动,而在短路线圈中产生很大的短路电流,导致线圈迅速发热而烧毁。

2.产生原因

电动机长期过载,使绝缘老化失去绝缘作用;嵌线时造成绝缘损坏;绕组受潮使绝缘电阻下降造成绝缘击穿;端部和层间绝缘材料没垫好或整形时损坏;端部连接线绝缘损坏;过电压或遭雷击使绝缘击穿;转子与定子绕组端部相互摩擦造成绝缘损坏;金属异物落入电动机内部和油污过多。

3.检查方法

⑴外部观察法。观察接线盒、绕组端部有无烧焦,绕组过热后留下深褐色,并有臭味。

⑵探温检查法。空载运行20分钟(发现异常时应马上停止),用手背摸绕组各部分是否超过正常温度。

⑶通电实验法。用电流表测量,若某相电流过大,说明该相有短路处。

⑷电桥检查。测量个绕组直流电阻,一般相差不应超过5%以上,如超过,则电阻小的一相有短路故障。

⑸短路侦察器法。被测绕组有短路,则钢片就会产生振动。

⑹万用表或兆欧表法。测任意两相绕组相间的绝缘电阻,若读数极小或为零,说明该二相绕组相间有短路。

⑺电压降法。把三绕组串联后通入低压安全交流电,测得读数小的一组有短路故障。

⑻电流法。电机空载运行,先测量三相电流,在调换两相测量并对比,若不随电源调换而改变,较大电流的一相绕组有短路。

4.短路处理方法

⑴短路点在端部。可用绝缘材料将短路点隔开,也可重包绝缘线,再上漆重烘干。

⑵短路在线槽内。将其软化后,找出短路点修复,重新放入线槽后,再上漆烘干。

⑶对短路线匝少于1/12的每相绕组,串联匝数时切断全部短路线,将导通部分连接,形成闭合回路,供应急使用。

⑷绕组短路点匝数超过1/12时,要全部拆除重绕。 绕组断路由于焊接不良或使用腐蚀性焊剂,焊接后又未清除干净,就可能造成壶焊或松脱;受机械应力或碰撞时线圈短路、短路与接地故障也可使导线烧毁,在并烧的几根导线中有一根或几根导线短路时,另几根导线由于电流的增加而温度上升,引起绕组发热而断路。一般分为一相绕组端部断线、匝间短路、并联支路处断路、多根导线并烧中一根断路、转子断笼。

1.故障现象

电动机不能启动,三相电流不平衡,有异常噪声或振动大,温升超过允许值或冒烟。

2.产生原因

⑴在检修和维护保养时碰断或制造质量问题。

⑵绕组各元件、极(相)组和绕组与引接线等接线头焊接不良,长期运行过热脱焊。

⑶受机械力和电磁场力使绕组损伤或拉断。

⑷匝间或相间短路及接地造成绕组严重烧焦或熔断等。

3.检查方法

⑴观察法。断点大多数发生在绕组端部,看有无碰折、接头出有无脱焊。

⑵万用表法。利用电阻档,对“Y”型接法的将一根表棒接在“Y”形的中心点上,另一根依次接在三相绕组的首端,无穷大的一相为断点;“△”型接法的短开连接后,分别测每组绕组,无穷大的则为断路点。

⑶试灯法。方法同前,等不亮的一相为断路。

⑷兆欧表法。阻值趋向无穷大(即不为零值)的一相为断路点。

⑸电流表法。电机在运行时,用电流表测三相电流,若三相电流不平衡、又无短路现象,则电流较小的一相绕组有部分短断路故障。

⑹电桥法。当电机某一相电阻比其他两相电阻大时,说明该相绕组有部分断路故障;

⑺电流平衡法。对于“Y”型接法的,可将三相绕组并联后,通入低电压大电流的交流电,如果三相绕组中的电流相差大于10%时,电流小的一端为断路;对于“△”型接法的,先将定子绕组的一个接点拆开,再逐相通入低压大电流,其中电流小的一相为断路。

⑻断笼侦察器检查法。检查时,如果转子断笼,则毫伏表的读数应减小。

4.断路处理方法

⑴断路在端部时,连接好后焊牢,包上绝缘材料,套上绝缘管,绑扎好,再烘干。

⑵绕组由于匝间、相间短路和接地等原因而造成绕组严重烧焦的一般应更换新绕组。

⑶对断路点在槽内的,属少量断点的做应急处理,采用分组淘汰法找出断点,并在绕组断部将其连接好并绝缘合格后使用。

⑷对笼形转子断笼的可采用焊接法、冷接法或换条法修复。 绕组接错绕组接错造成不完整的旋转磁场,致使启动困难、三相电流不平衡、噪声大等症状,严重时若不及时处理会烧坏绕组。主要有下列几种情况:某极相中一只或几只线圈嵌反或头尾接错;极(相)组接反;某相绕组接反; 多路并联绕组支路接错;“△”、“Y”接法错误。

1、故障现象

电动机不能启动、空载电流过大或不平衡过大,温升太快或有剧烈振动并有很大的噪声、烧断保险丝等现象。

2、产生原因

误将“△”型接成“Y”型;维修保养时三相绕组有一相首尾接反;减压启动是抽头位置选择不合适或内部接线错误;新电机在下线时,绕组连接错误;旧电机出头判断不对。

3.检修方法

⑴滚珠法。如滚珠沿定子内圆周表面旋转滚动,说明正确,否则绕组有接错现象。

⑵指南针法。如果绕组没有接错,则在一相绕组中,指南针经过相邻的极(相)组时,所指的极性应相反,在三相绕组中相邻的不同相的极(相)组也相反;如极性方向不变时,说明有一极(相)组反接;若指向不定,则相组内有反接的线圈。

⑶万用表电压法。按接线图,如果两次测量电压表均无指示,或一次有读数、一次没有读数,说明绕组有接反处。

⑷常见的还有干电池法、毫安表剩磁法、电动机转向法等。

4.处理方法

⑴一个线圈或线圈组接反,则空载电流有较大的不平衡,应进厂返修。

⑵引出线错误的应正确判断首尾后重新连接。

⑶减压启动接错的应对照接线图或原理图,认真校对重新接线。

⑷新电机下线或重接新绕组后接线错误的,应送厂返修。

⑸定子绕组一相接反时,接反的一相电流特别大,可根据这个特点查找故障并进行维修。

⑹把“Y”型接成“△”型或匝数不够,则空载电流大,应及时更正。怎样测量三相异步电动机六股引出线的相同端头用干电池和万用表判别, 保养方法连续运转的三相异步电动机,日常保养内容:外观检查,风扇是否工作正常,是否有异常振动,联轴器连接是否可靠,底座固定是否紧固,轴承工作是否正常(听声音),温度是否正常(红外测温仪),定期检查电线接头和开关触点,工作电流是否正常(钳型电流表),另外绕线式电机还须检查碳刷和滑环。 测量端头⑴先判别三相绕组的各自的两个首尾端.将万用表调到电阻档进行测量,凡是同一相的线圈就相连接没有阻值,凡不是同一相的线圈就不相通,因此根据万用表可分清两个线端属于同一相绕组引出线。

⑵判别其中两侧线圈引出线的同名端,将指针式万用表调到量程最小的直流电流档,再将任意一相的绕组的两个线端接到表上,然后将另一相绕组的两个线端一同分别瞬时碰触一下干电池的正极和负极,在干电池与线圈接通的一瞬间如果表针摆向大于零的一边(也就是顺时针摆动),则电池正极和万用表黑色表笔为同名端,逆则反矣。

百度翻译字数限制为5000字, "串联匝"及其后面没有被翻译!

The winding is part of the motor, aging, moisture, heat, erosion, xenembole the impact of the external force can cause damage to the winding, motor overload, under voltage, over voltage, phase lack operation can cause the winding fault. Winding fault is generally divided into winding grounding, short circuit, open circuit, wiring error. The fault phenomena, causes and inspection methods are explained respectively. The grounding of the winding earth finger winding and the iron core or insulation damage to the casing.

1, fault phenomenon

The shell is charged, the control circuit is out of control and the winding is short circuited.

2, cause

Winding insulation resistance decreased damp motor; long-term overload operation; harmful gas corrosion; metal xenembole winding internal insulation damage; damage to touch the core insulation of stator winding coil; the winding end touch base cover the stator and rotor friction caused by insulation; burn; lead wire insulation damage and shell together; over voltage (such as lightning). Insulation breakdown.

3 inspection methods

The observation method. Through the visual winding ends and the line slot insulation for any damage and observe the blackened traces, if it is to take place.

The multimeter test. Multimeter with low resistance check, reading is very small, it is grounded.

The megohmmeter method. According to the different levels of insulation resistance with different zhaooubiao measureeach group resistance, if reading is zero, said the windinggrounding, but to motor insulation damp or by accident and breakdown, to judge on the basis of experience, generally speaking pointer in the 0 place withoutswaying timing can think it has certain the resistance value.

The lamp test method. If the test light is bright, it is shown that the winding is grounded, and if it is found to be accompanied by a spark or a smoke, the ground fault point. If the lamp is light, the insulation is grounded. If the lamp does not light, but also when the test rod grounding sparks, indicating that the winding has not yet breakdown, but only severely damp. Also available in the mouth of the hardwood shell tapping edge knock to a place, a light one out, that current when the broken, then it is take place.

The current wear method. With a voltage regulating transformer, connected to the power supply, the site quickly heating, insulation smoke is the place of contact. Special attention should be paid to the small motor should not exceed two times the rated current, the time is not more than half a minute; large motor rated current of 20%-50% or gradually increase the current, to the point of contact when the smoke immediately cut off.

Such as packet elimination method. To take place in the core of my heart and burningis better, the burning of the copper and iron core melt together. The method is to divide the ground phase winding into two halves.

In addition, there are high pressure test method, magnetic exploration method, vibration method and so on, here is not introduced one by one.

4 processing methods

The ground should be drying caused by damp winding, when cooled to 60 - 70 degrees Celsius, insulating paint poured after drying.

At the end of the winding insulation damage, on the ground to be insulated, painting, drying.

The windings to place in the slot should be rewound, winding or replace part of the winding element.

Finally, the application of different measurements to meet the technical requirements. Winding short circuit due to excessive current motor power supply voltage change is too large, single operation, mechanical bruising poor insulation damage caused by making to points, winding short circuit winding short circuit winding short circuit and winding short circuit.

1 fault phenomena

The magnetic field distribution of ions is uneven, unbalanced three-phase current and the motor running vibration and noise increase, motor can start serious, resulting in large short-circuit current short-circuit coil, lead to coil heating and quickly destroyed.

2 cause

Motor overload for a long time, the aging loss of insulation insulation; wire insulation damage caused by damp; winding insulation resistance decreased due to insulation breakdown; and the end of the interlayer insulating material is not damaged or plastic pad good; end connecting line insulation damage; overvoltage or lightning insulation breakdown; the rotor and the stator winding end Department of friction between the insulation damage caused by metallic foreign bodies into the interior of the motor; and too much oil.

3 inspection methods

The external observation method. Observe the junction box, the end of the winding is not burning, winding overheating left dark brown, and smell.

The temperature probe test method. No-load running 20 minutes (found abnormal should immediately stop), with the back of the hand to touch the winding part is more than the normal temperature.

The electricity experiment. If the current is too large, it is shown that the phase is short circuited.

Check the bridge. Measurement of winding DC resistance, the general difference should not be more than 5%, such as more than a small resistance to a short-circuit fault.

The short circuit detector method. If the measured winding is short circuited, the steel will vibrate.

Such a multimeter or megohmmeter method. The insulation resistance of any two phase winding is measured. If the reading is small or zero, the phase winding is short circuited.

Is the voltage drop method. After the three windings are connected in series, the low voltage safe alternating current is measured.

According to the current law. Motor no-load operation, the first measurement of three-phase current, in the exchange of two-phase measurement and comparison, if not with the power exchange and change, a large current phase winding short-circuit.

4 short circuit processing method

The short-circuit point in the end. The available insulating material to the short-circuit point can also be separated from the insulated wire, and then re drying paint.

The short line slot. The softening, find out the short point of repair, back into the slot, then paint drying.

The shortest route to turn to less than 1/12 per phase winding,

-

Overview of three phase induction motors2016-12-29

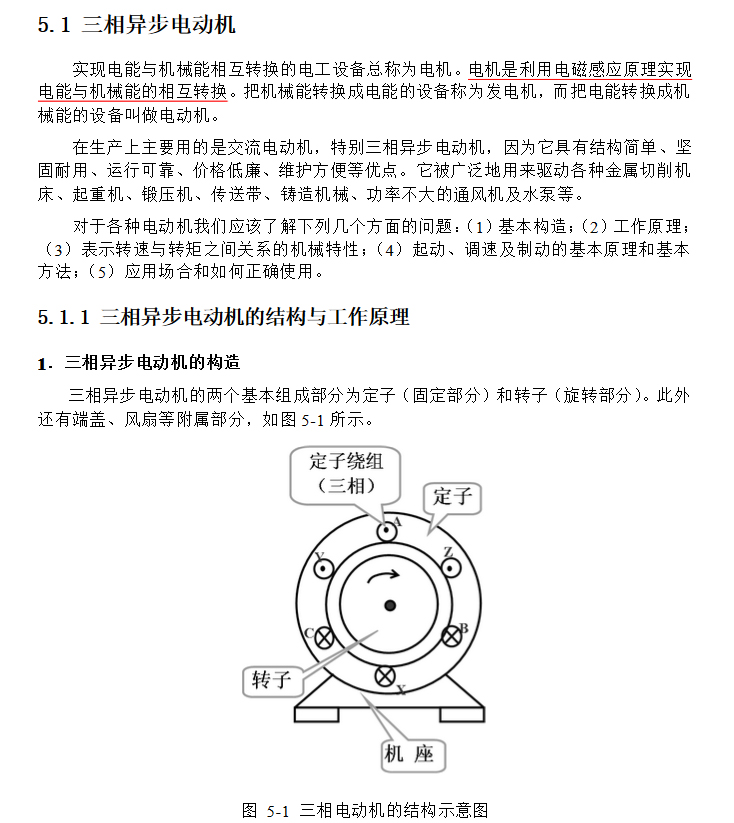

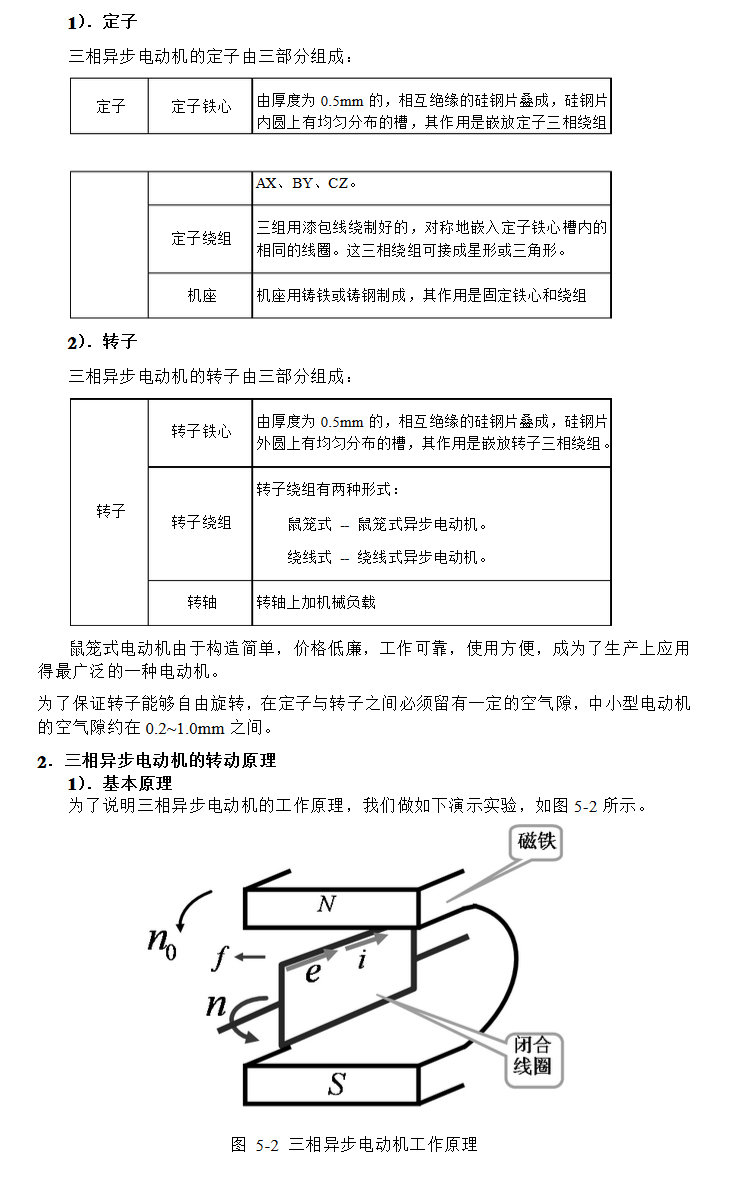

Overview of three phase induction motors2016-12-29Three phase asynchronous motor for motor operation. Three phase asynchronous motor rotor speed below the speed of a rotating magnetic field, the rotor winding magnetic field between the relative motion and the induced electromotive force and current, and electromagnetic torque and magnetic field interaction, realize the energy transformation. Compared with the single-phase asynchronous motor, the three-phase asynchronous motor has good performance and can save all kinds of materials. According to the different rotor structure, three-phase asynchronous motor can be divided into two types of cage and winding. The squirrel cage rotor asynchronous motor has been widely used because of its simple structure, reliable operation, light weight and low price. Winding type three-phase asynchronous motor rotor and stator windings and also set up by slip ring, brush and external rheostat connection. Adjust rheostat resistance can improve the starting performance of the motor and adjust the motor speed.

Compared with the single-phase asynchronous motor, the three-phase asynchronous motor has good performance and can save all kinds of materials. According to the different rotor structure, three-phase asynchronous motor can be divided into two types of cage and winding. The squirrel cage rotor asynchronous motor has been widely used because of its simple structure, reliable operation, light weight and low price. Winding type three-phase asynchronous motor rotor and stator windings and also set up by slip ring, brush and external rheostat connection. Adjust rheostat resistance can improve the starting performance of the motor and adjust the motor speed.